ViscoTwin Pumps Options

The ViscoTwin

screw pump provides a range of options that allow adaption to many different

situations. Please contact us if your needs are different and the options you

are looking for do not appear.

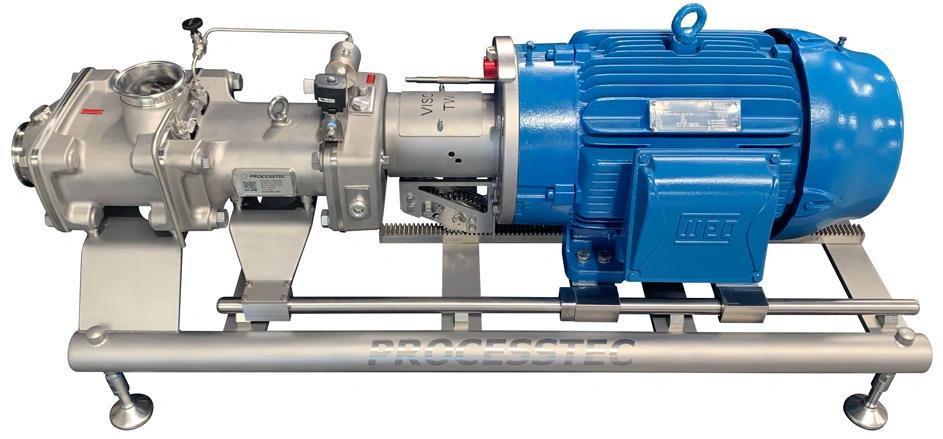

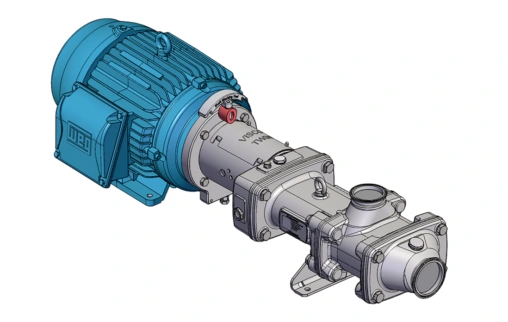

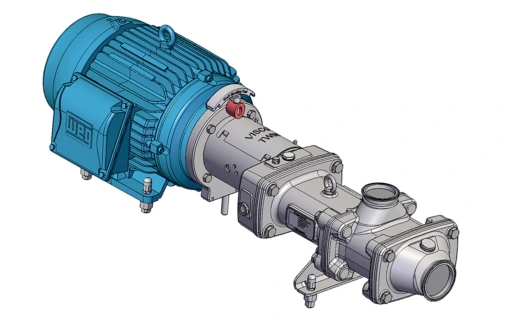

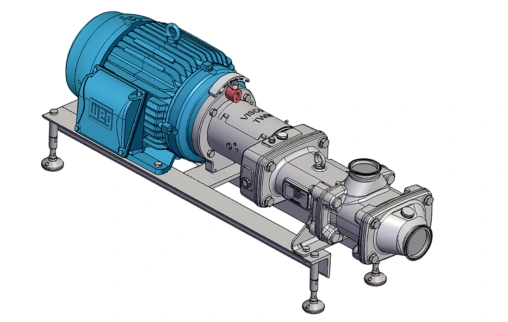

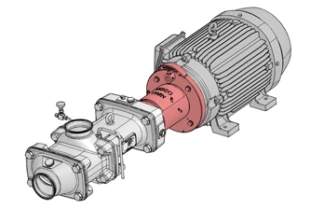

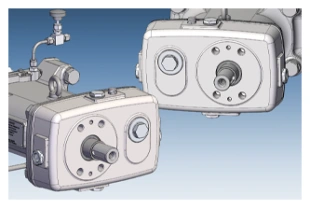

Here is a ViscoTwin 130 G10, featuring a Seal Water Automation Kit and Disengaging Coupler, mounted on Frame #4.

SANITARY DESIGN PRACTICES

All Spindles are surface hardened to 1200 HV (72 Rockwell).

The general build of all ViscoTwin pumps also fulfills OSHA guidelines.

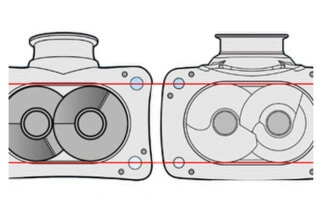

100% Drainability

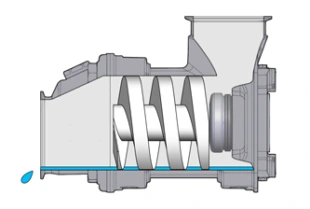

The ViscoTwin design allows 100% drainability.

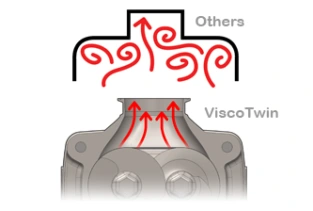

No Dead Spots

The interior walls of the ViscoTwin G10 Pump Housing have been streamlined for the smoothest possible pumping of product, increasing efficiency and avoiding dead spots.

Repositioned Sealing Area

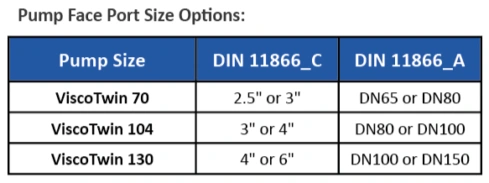

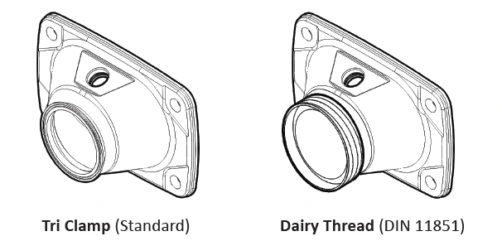

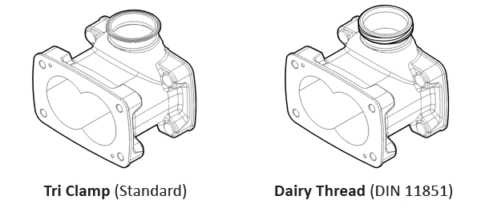

PUMP FACE OPTIONS

NPSH Optimized Pump Face

Dual Port Pump Face

Weld-In Flange

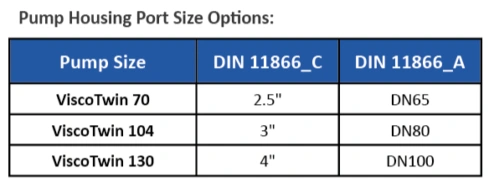

PUMP HOUSING OPTIONS

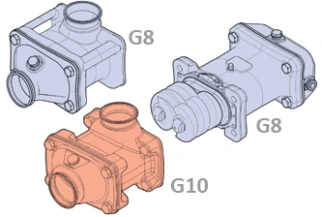

The G10 Pump Housing was designed to facilitate gentle product flow without damaging particulates. The G10 Pump Housing is also backwards compatible to the G8 on both the 104 and 130 models.

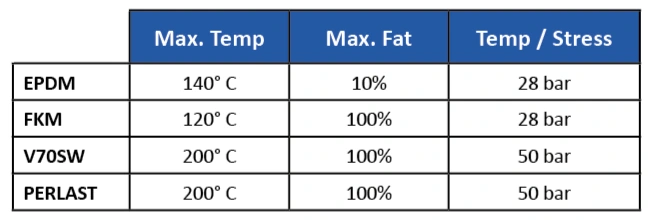

ELASTOMER OPTIONS

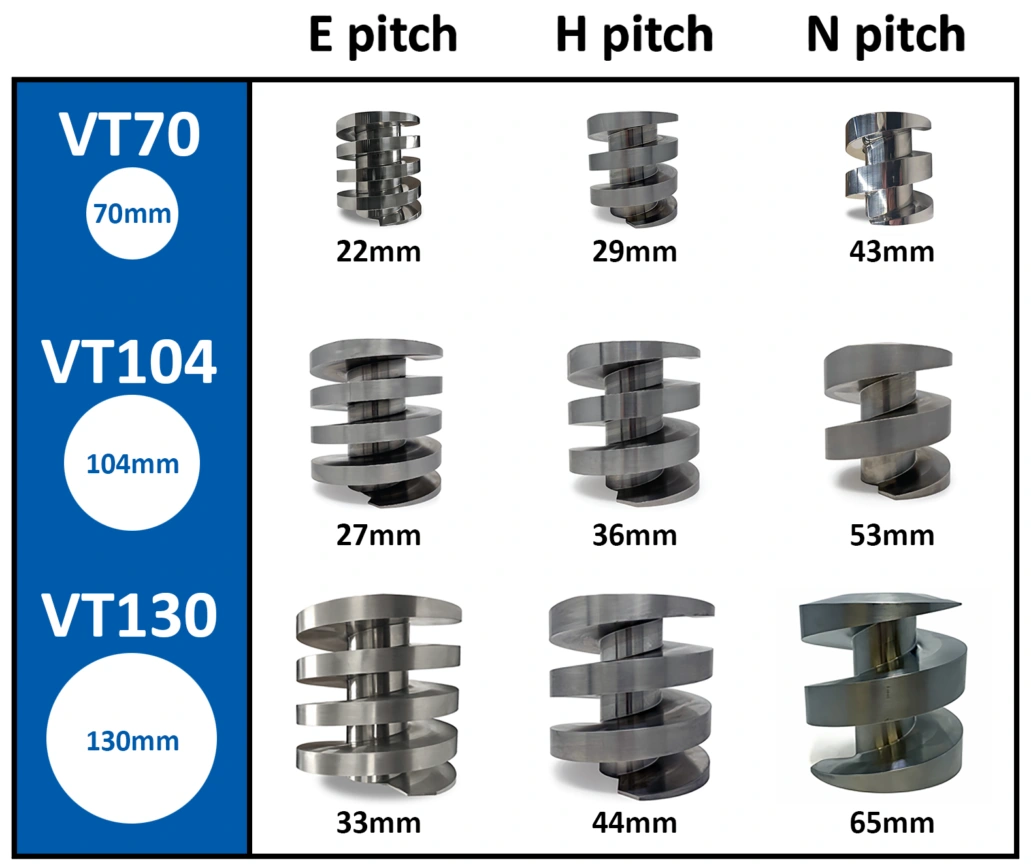

SPINDLE OPTIONS

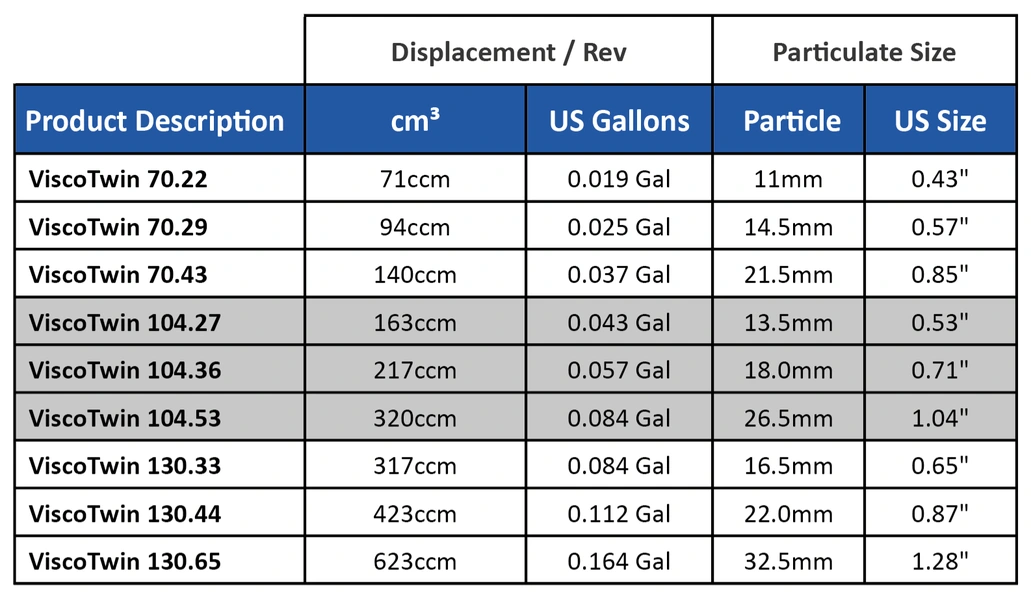

For high discharge pressures, the smaller pitches are used. Smaller spindle pitches are used to create high discharge pressure. Lower spindle pitches result in less volume/revolution. High discharge pressures are easier to reach with increasing viscosity.

For product with specific particulate sizes, the spindle pitch will determine the minimum pump size. For example, if the particulate requires a cross section of 1", then the pump would need to be a Model 104.53 or Model 130.65.

MECHANICAL SEAL OPTIONS

Different mechanical sealing surfaces and elastomers are available for the ViscoTwin G10 pumps. Material and design are selected based on application. For easy handling, the ViscoTwin G10 is designed to use a fully assembled cartridge seal to prevent installation errors and damages to the sealing surfaces.

Double Acting Mechanical Seals (DAMS)

ViscoTwin G10 pumps with double acting mechanical seals can run dry as long as the quench media flows through the seal. The quench media lubricates and cools the sealing surfaces whether there is product in the pump or not.

Sealing Surface:

Tungsten Carbide knife edge (TC). This surface is ideal, as it is metal detectable.

FRAME OPTIONS

Frame 1

Frame for Skid Mount

With Frame 1, the Pump head support bracket is aligned with the Motor. This setup is used to install the pump on a custom skid.

Frame 2

Standard Frame

Frame 2

features Frame 1 plus 6x height adjustable feet in stainless to align pump head

and motor with tilted or uneven floors.

Frame 3

4-Leg Frame

The classic frame with FOUR (4) leveling feet.

Frame 4

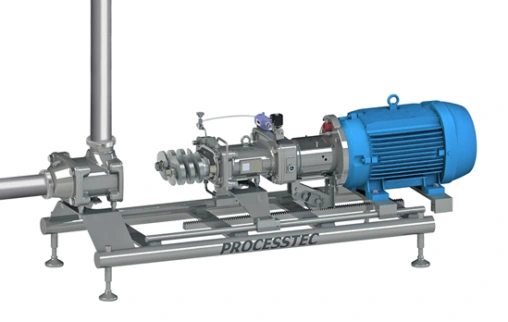

Maintenance-in-place Frame

Frame 4 is the culmination of many years of field experience in the industry. It was designed to be able to streamline periodic maintenance while increasing WORKPLACE SAFETY. In-place sanitary inspection can occur without disconnecting upstream and downstream pipes.

Frame 5

PumpcartThe Frame 5 Pumpcart is designed to be the ultimate in portable solutions. Not only is the entire unit fully mobile on wheels and casters, the VFD is integrated into the cart, meaning you can utilize this pump wherever you can maneuver it to.

The Frame 5 Pumpcart is designed to be the ultimate in portable solutions. Not only is the entire unit fully mobile on wheels and casters, the VFD is integrated into the cart, meaning you can utilize this pump wherever you can maneuver it to.

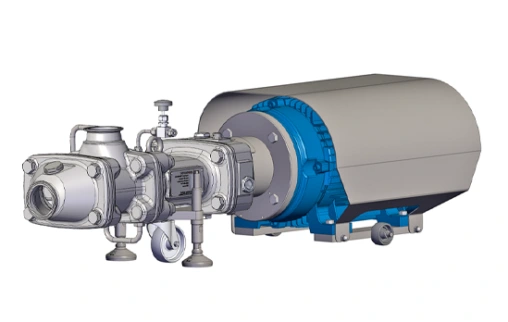

Frame 6

Kettle Frame

The Frame 6 can slide underneath tanks and kettles when space is constrained, and features a Motor Hood that prevents spilled product and from accumulating on the Motor Fins. This Hood makes cleaning as simple as possible, without taking up too much extra space.

FEATURES

Visco Twin Lantern

The ViscoTwin Lantern perfectly aligns the Motor to the Pumphead. The sturdy design allows the pump to achieve high RPM’s, and facilitates the use of our Shaft Blocking Tool and Disengaging Coupler.

Shaft Blocking Tool

This tool fits into the ViscoTwin Lantern opening and prevents the Coupler, Spindles and Shafts from rotating while the Pump is under maintenance. This not only SAVES TIME, it increases SAFETY.

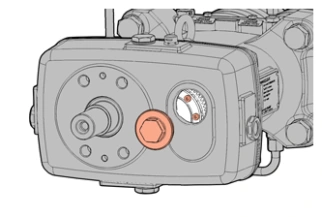

Gapping Port

Designed to allow EASY ACCESS to the Gear Synchronization Lock Ring for timing & gapping procedures.

Also allows for the potential installation of various monitoring sensors.

Dual Oil Sight Glasses

Each ViscoTwin Pump includes TWO (2) Oil Sight Glasses, one on each side of the Gear Housing, so that a visual confirmation of oil levels can be easily achieved when space is constrained or limited.

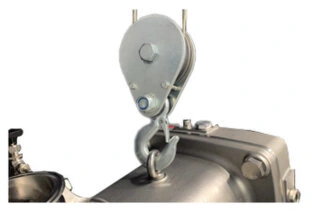

Lifting Hook

Every ViscoTwin Pump includes a Lifting Hook for safe pump handling. This Lifting Hook fully supports the weight of the pump.

Backwards Compatibility (to G8 & WangenTwin)

The ViscoTwin G10 was engineered to have backwards compatibility with the previous generation of ViscoTwin, as well as certain WangenTwin pumps.

OPTIONS / ACCESSORIES

Shaft Orientation (LEFT or RIGHT)

The ViscoTwin is available with a LEFT or RIGHT shaft orientation. Drive Shaft left with motor TEFC Box in F1 position is the standard.

Seal Water Automation Kit

Allows you to insure the supply of seal water to both Mechanical Seals in series. Includes a Flow Meter with Set Point, a Solenoid or Pneumatic Shut-Off Valve. Piping as well as compression fittings are in stainless steel.

Disengaging Coupler (Torque Limiter)

This option automatically disengages the Motor Shaft from the Pump Drive Shaft in the event of a blockage in the Spindle Area, preventing catastrophic damage to the pump. The pump coupler also hosts the bore for the Shaft Blocking Tool.

HIGH PRESSURE / HIGH TEMP OPTIONS

The standard mechanical seals are designed to withstand a product area pressure of up to 400 psi. With High Pressure Seals, the product area pressure can reach up to 650 psi.

These seals are only available in a specially designed HPHT (High Pressure, High Temperature) ViscoTwin, which can be built to withstand temperatures of up to 380 degrees Fahrenheit!

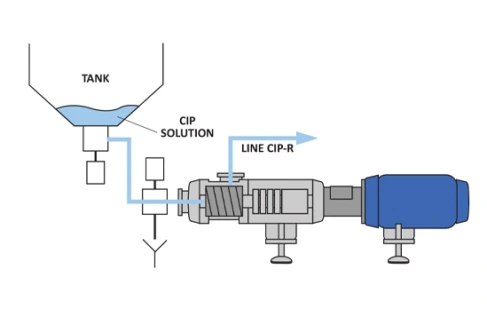

CIP OPTIONS

The available CIP

options for use with PROCESSTEC’s ViscoTwin pumps are outlined below.

Self-Propelled Cleaning (CIP)

The pump is used as a CIP return pump. This is mostly the case when a pump is installed as a tank discharge pump. The Max Flowrate is according to the pump curve for viscosity 1 cps.

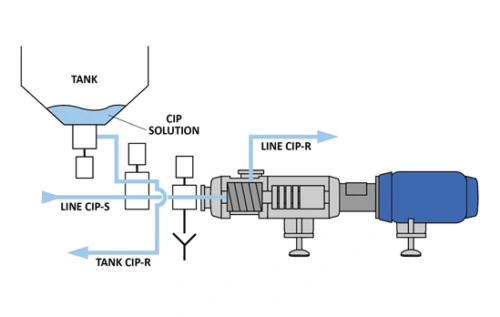

Inline Cleaning (CIP)

Max Flowrate depending on differential pressure only. The pump does not need to propel the CIP solution and is part of the cleaned pipe line. A dedicated CIP pump upstream is propelling the CIP solution.

MOTOR OPTIONS

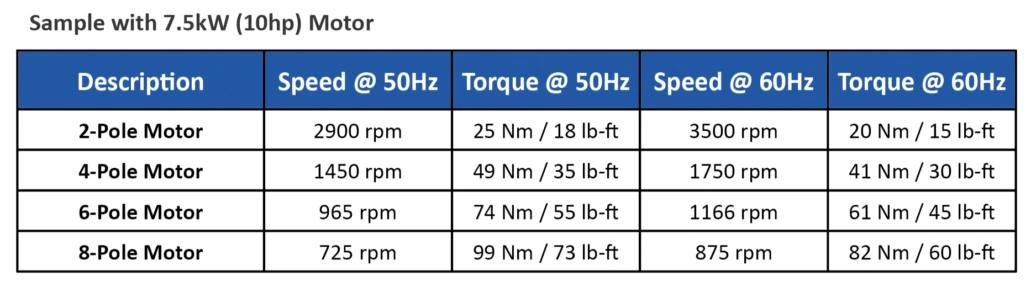

ViscoTwin pump motors are optimized to deliver max torque in the 300 to 1200 rpm range at the lowest performance requirement to save cost & complexity.

Gearmotors

Gearmotors are selected when higher torque is needed at lower power & CIP boosting isn’t required. The general limit on gearboxes for overspeeding is 1.5x to 2x to nominal speed.

The generic rule of thumb is:

Metric: (kW x 9549) = RPM x Torque in Nm

Imperial: (HP x 5252) = RPM x Torque in lb-ft.The torque value of an electric motor is approximately flat between 30 Hz to 60 Hz. Above 60 Hz, the formulas above apply. Below 25 Hz, the loss in torque needs to be calculated.