SmartConnect Valving System Overview

Using piping technology from GEA, PROCESSTEC has developed an innovative piping system for the food, dairy and beverage industries. The integrated pigging technology enables a streamlined system with fewer pumps, less product loss, fewer CIP cycles and less floor space.

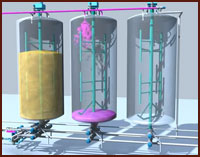

SmartConnect with Integrated Pigging System

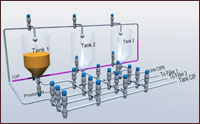

Traditional Valve Manifold System with:

System with:

1 fill line, piggable

2 discharge lines, piggable

1 CIP-Supply

1 CIP-Return

System with:

1 fill line, non piggable2 discharge lines, non piggable

1 CIP-Supply

1 CIP-Return

Why SmartConnect?

For Operations:

- Streamlined system design with fewer pumps – Because there is less of a pressure drop in the suction line from the tank to the pump, fewer pumps are required, even for high-viscosity and shear-sensitive products

- Zero production loss – An integrated pigging system in product lines (fill and discharge) makes this possible

- Fewer CIP cycles – The use of short coupled mixproof valves to the tank itself requires fewer cycles

- Less floor space required – The entire system is more efficient and compact

- Cleaner operations – The integrated pigging system and fewer discharge lines makes it easier to keep the floor clean

- Better valve access for easy removal of valves with PROCESSTEC’s height adjustable maintenance cart

- Easy access to agitator bearings through removable bottom plate (no confined space entry necessary), making regular bearing checks by operations personnel possible

- Fewer valves to maintain

For Installation

- Very high design flexibility to enable 24/7 operation in narrow silo hallways with mixproof technology

- Short system downtimes for installation because of modular pre-fabrication (hours versus days)

- Fast installation due to pre-fabricated pipes – also for double walled systems to allow for product cooling or heating

- Fewer valves to install and automate, while accomplishing the same system functionality