VT 130 G10 Landing Page

Landing Page

ViscoTwin 10

Overview

ViscoTwin pumps are setting a new standard for sanitary design. The mechanical seals are fully exposed to 100% of the passing CIP liquid and the pump is 100% drainable by design. There are almost no limitations in media viscosity, pumping product from water to silicone at discharge pressures from 230 to 360 psi. With dual mechanical seals, the pumps can run dry for extended periods. It primes low viscous media up to 3 feet and operates with extremely high suction at an NPSH of 3 to 4 feet. It does not get airborne ever. The pump is fully by-directional.

ViscoTwin G10, ....

ViscoTwin G10, ....

ViscoTwin G10, ....

ViscoTwin G10, ....

Overview

ViscoTwin pumps are setting a new standard for sanitary design. The mechanical seals are fully exposed to 100% of the passing CIP liquid and the pump is 100% drainable by design. There are almost no limitations in media viscosity, pumping product from water to silicone at discharge pressures from 230 to 360 psi. With dual mechanical seals, the pumps can run dry for extended periods. It primes low viscous media up to 3 feet and operates with extremely high suction at an NPSH of 3 to 4 feet. It does not get airborne ever. The pump is fully by-directional.

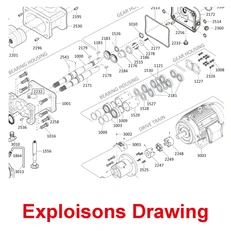

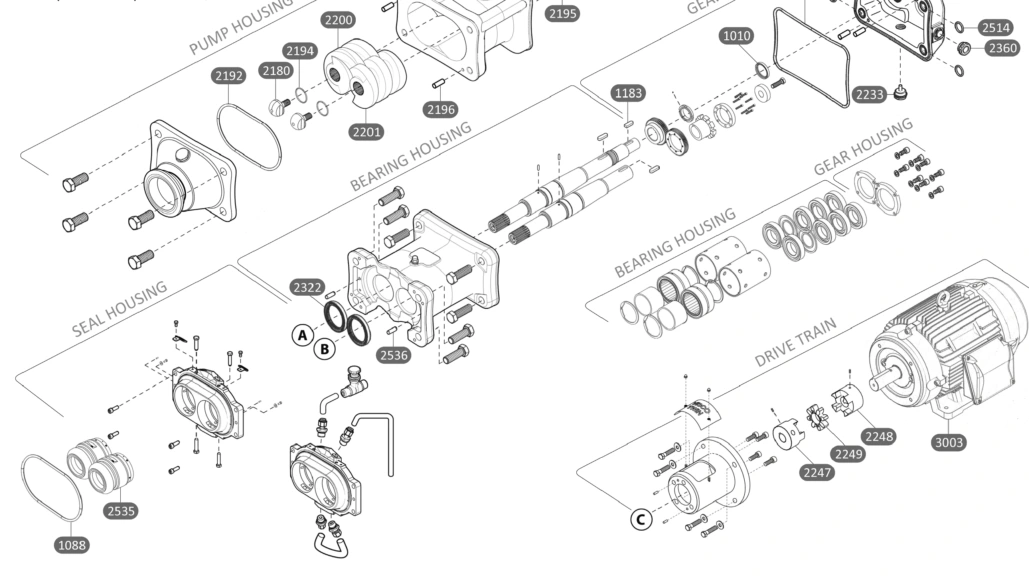

Explosions Drawing

Downloads

Download

Download

Download

Download

Download

Download

Download

Download

Download

Download